Navigating the Globe of Fasteners and Machining: Techniques for Precision and Speed

In the detailed realm of bolts and machining, the mission for accuracy and rate is a continuous difficulty that requires precise interest to detail and strategic preparation. From recognizing the varied variety of bolt kinds to choosing ideal products that can stand up to strenuous needs, each step in the process plays an essential function in accomplishing the preferred result.

Understanding Fastener Types

When choosing bolts for a project, recognizing the numerous types readily available is vital for ensuring optimum performance and integrity. Bolts are utilized with nuts to hold materials with each other, while screws are flexible bolts that can be used with or without a nut, depending on the application. Washers are essential for distributing the tons of the bolt and avoiding damage to the product being attached.

Choosing the Right Products

Recognizing the importance of choosing the appropriate products is paramount in guaranteeing the optimum efficiency and reliability of the selected fastener kinds reviewed formerly. When it pertains to bolts and machining applications, the material selection plays a vital duty in determining the overall stamina, toughness, deterioration resistance, and compatibility with the designated setting. Various products offer varying properties that can considerably affect the performance of the fasteners.

Usual materials used for bolts consist of steel, stainless-steel, titanium, brass, and aluminum, each having its distinct staminas and weaknesses. Steel is renowned for its high strength and resilience, making it suitable for a wide variety of applications. Stainless-steel supplies superb rust resistance, ideal for environments vulnerable to moisture and chemicals. Light weight aluminum is corrosion-resistant and lightweight, making it suitable for applications where weight decrease is essential. Brass is frequently chosen for its visual allure and exceptional conductivity. Titanium is understood for its phenomenal strength-to-weight proportion, making it suitable for high-performance applications. Choosing the best material entails thinking about elements such as strength demands, ecological problems, and spending plan constraints to guarantee the desired efficiency and long life of the fasteners.

Precision Machining Techniques

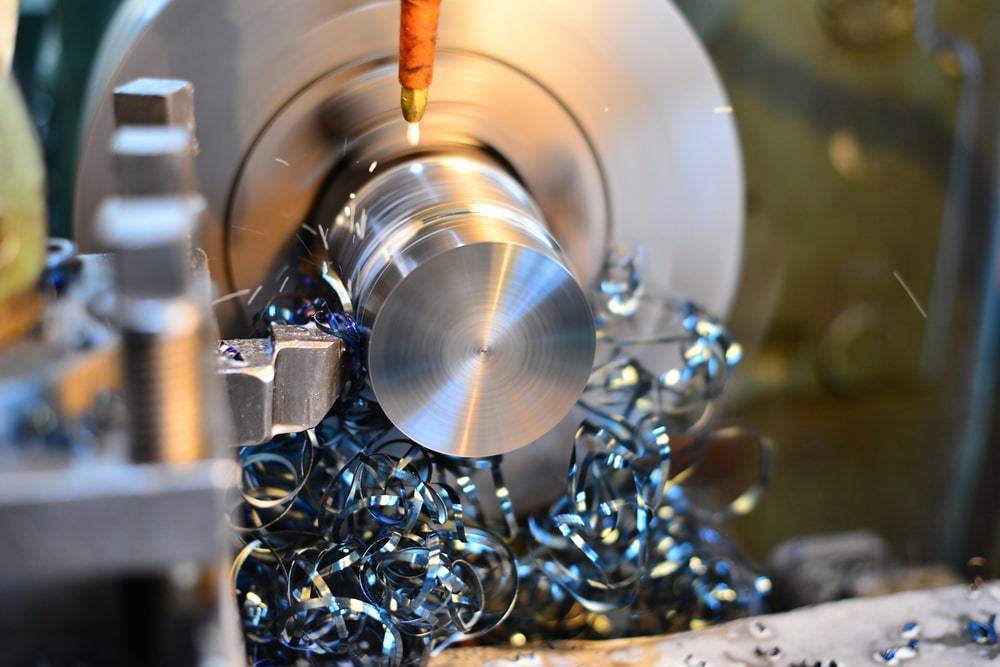

In addition to CNC machining, other precision strategies like grinding, turning, milling, and boring play vital functions in bolt production. Grinding assists accomplish fine recommended you read surface area coatings and tight dimensional resistances, while turning is commonly used to produce round components with specific diameters. Milling and boring procedures are vital for forming and creating holes in fasteners, guaranteeing they meet specific requirements and function correctly.

Enhancing Speed and Efficiency

To maximize fastener manufacturing processes, it is crucial to enhance operations and execute effective approaches that complement precision machining methods. One crucial approach for boosting speed and effectiveness is the application of lean production concepts. By decreasing waste and concentrating on constant enhancement, lean methods assist maximize and remove traffic jams operations. In addition, buying automation technologies can substantially enhance manufacturing rate. Automated systems can manage recurring jobs with accuracy and speed, enabling workers to concentrate on more complex and value-added tasks. Taking On Just-In-Time (JIT) supply monitoring can likewise enhance effectiveness by making sure that the ideal materials are available our website at the correct time, minimizing excess inventory and reducing lead times. Moreover, promoting a culture of collaboration and interaction amongst employee can boost general effectiveness by promoting openness, problem-solving, and innovation. By combining these approaches, producers can achieve an equilibrium between rate and precision, ultimately enhancing their competitive side in the fastener market.

High Quality Control Actions

Carrying out extensive quality control actions is vital in making sure the dependability and uniformity of fastener items in the manufacturing procedure. Fasteners and Machining. Quality control measures include different phases, beginning from the option of raw products to the last evaluation of the finished bolts. This includes assessing variables such as material resilience, make-up, and strength to guarantee that the fasteners fulfill industry requirements.

Normal calibration of devices and equipment is crucial to maintain consistency in manufacturing and ensure that fasteners fulfill the required tolerances. Executing rigorous protocols for determining and resolving problems or non-conformities is vital in preventing substandard products from going into the marketplace. By establishing a comprehensive top quality control structure, manufacturers can support the online reputation of their brand and deliver fasteners that satisfy the highest possible requirements of performance and resilience.

Verdict

In the complex world of fasteners and machining, the mission for accuracy and rate is a continuous obstacle that requires precise interest to information and calculated preparation. When it comes to bolts and machining applications, the product choice plays a crucial function in identifying the total toughness, toughness, corrosion resistance, and compatibility with the intended atmosphere. Accuracy machining includes various advanced approaches that make certain the tight tolerances and specifications needed for bolts.In enhancement to CNC machining, other precision strategies like grinding, transforming, navigate here milling, and boring play vital duties in fastener production.To optimize fastener production procedures, it is important to streamline procedures and carry out effective methods that match precision machining strategies.